The Moorfeed Difference

At Moorfeed, we are more than a fancy mission statement or contractual agreement. We are a team of specialists dedicated to providing our customers with solutions to problems others cannot solve. We are a firm handshake of callused hands with the sole purpose of achieving any goal set forth by ourselves or our customers. We do not rest on our laurels, yet take pride in the equipment we produce, without fear of improvement or failure, knowing ultimately, the proof is in the product.

Discover

Moorfeed Products

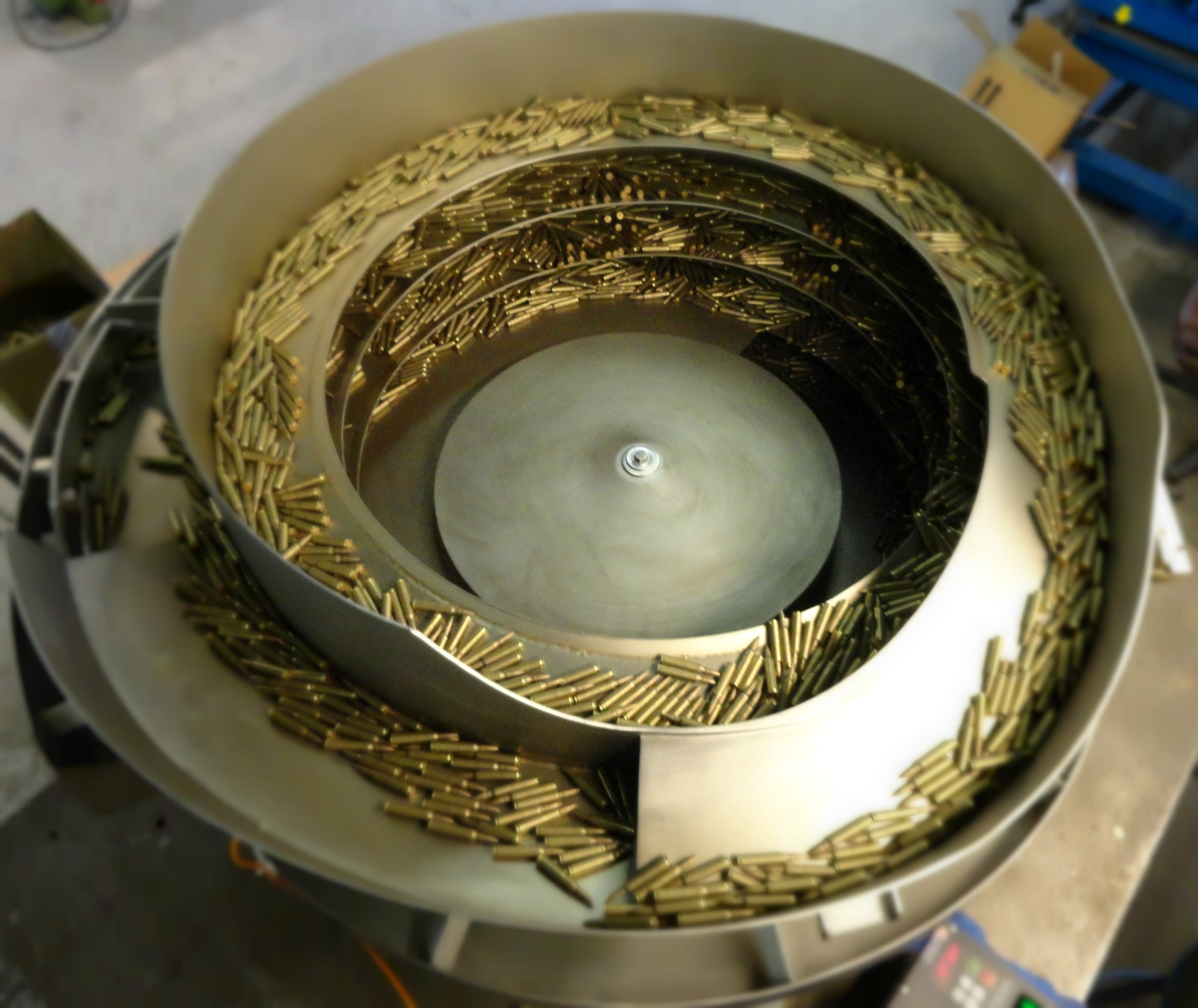

Moorfeed’s name has always been synonymous with quality and heavy duty equipment and we have continued this trend with the designs of our centrifugal feeders, table and frameworks, elevators, bulks storage and our vibratory feeders.

The Gold Standard

Highly Skilled Fabricators

Our fabricators have combined experience of over 500 years in bowl tooling. We build the most complex and intricate feeds systems and have succeeded where others haven’t even taken a chance.

Find a Rep Near You

We have knowledgeable sales representatives throughout North America.

Use the map below to get connected.