Importance of Integration Between Vibratory Feeders and Robots

The integration of vibratory feeders and robots is pivotal in modern manufacturing and automation, enhancing efficiency, precision, and flexibility in production processes. Below is a summary of its key benefits:

1. Enhanced Efficiency and Productivity

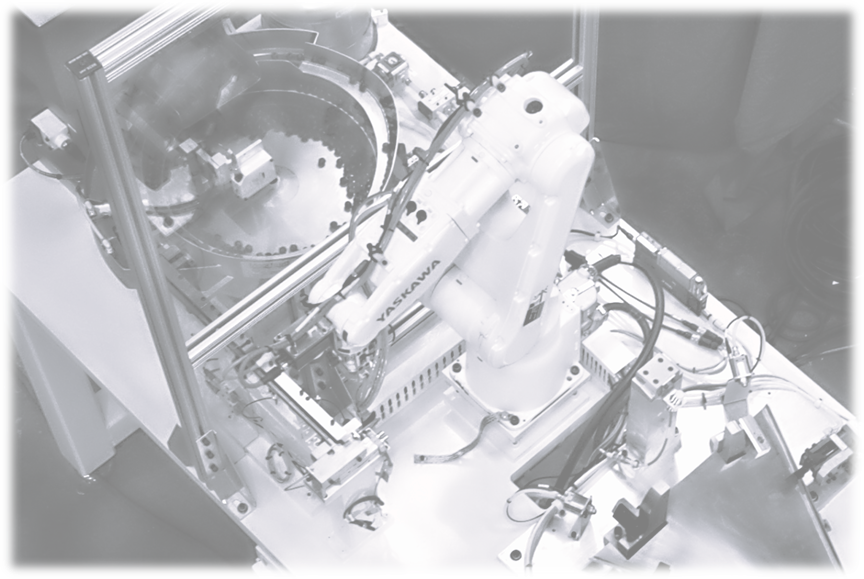

Vibratory feeders deliver parts in a consistent, organized manner, enabling robots to pick and place components with minimal downtime. This seamless material flow reduces cycle times and boosts throughput, critical for high-volume production environments.

2. Improved Precision and Accuracy

Vibratory feeders orient parts uniformly, ensuring robots can grasp them at predictable positions. This precision minimizes errors in assembly or processing, improving product quality and reducing waste.

3. Flexibility and Adaptability

Integrated systems can handle diverse part types and sizes by adjusting feeder settings and robot programming. This adaptability supports quick changeovers in production lines, accommodating varied manufacturing needs without extensive retooling.

4. Cost-Effectiveness

By automating material handling and part orientation, vibratory feeders reduce the need for manual labor, lowering operational costs. Robots, paired with feeders, execute repetitive tasks efficiently, maximizing return on investment.

5. Scalability for Industry 4.0

Integration aligns with smart manufacturing principles, enabling real-time data exchange and process monitoring. Sensors and IoT-enabled feeders can communicate with robots, optimizing performance and supporting predictive maintenance.

6. Enhanced Safety

Automating part feeding and handling reduces human intervention in hazardous tasks, improving workplace safety. Robots and feeders operate in sync to maintain consistent, safe workflows.

Conclusion

The synergy between vibratory feeders and robots streamlines automation, delivering high efficiency, precision, and adaptability. This integration is essential for modern industries aiming to optimize production, reduce costs, and align with advanced manufacturing trends.