REO Controllers vs. Solid State controls in Vibratory Feeder Applications

To compare a REO vibratory controller to a generic solid-state vibratory controller, we need to examine their functionality, features, and applications in vibratory feeder systems. REO vibratory controllers, under the REOVIB brand, are specialized control units designed for vibratory systems, widely used in automation for feeding, sorting, and conveying materials. Solid-state vibratory controllers, as a broader category, include various electronic control systems (including REO’s) that use solid-state components like thyristors or triacs for precise control without mechanical relays. Since REO controllers are a type of solid-state controller, we will compare REO’s specific offerings to general solid-state vibratory controllers, highlighting distinctions where applicable.

1. Technology and Operation

-

REO Vibratory Controllers:

-

Phase-Angle Control: REOVIB SMART and MTS series use thyristors or triacs for phase-angle control, adjusting voltage to the feeder’s magnet to control vibration amplitude. This provides precise regulation of material flow.

-

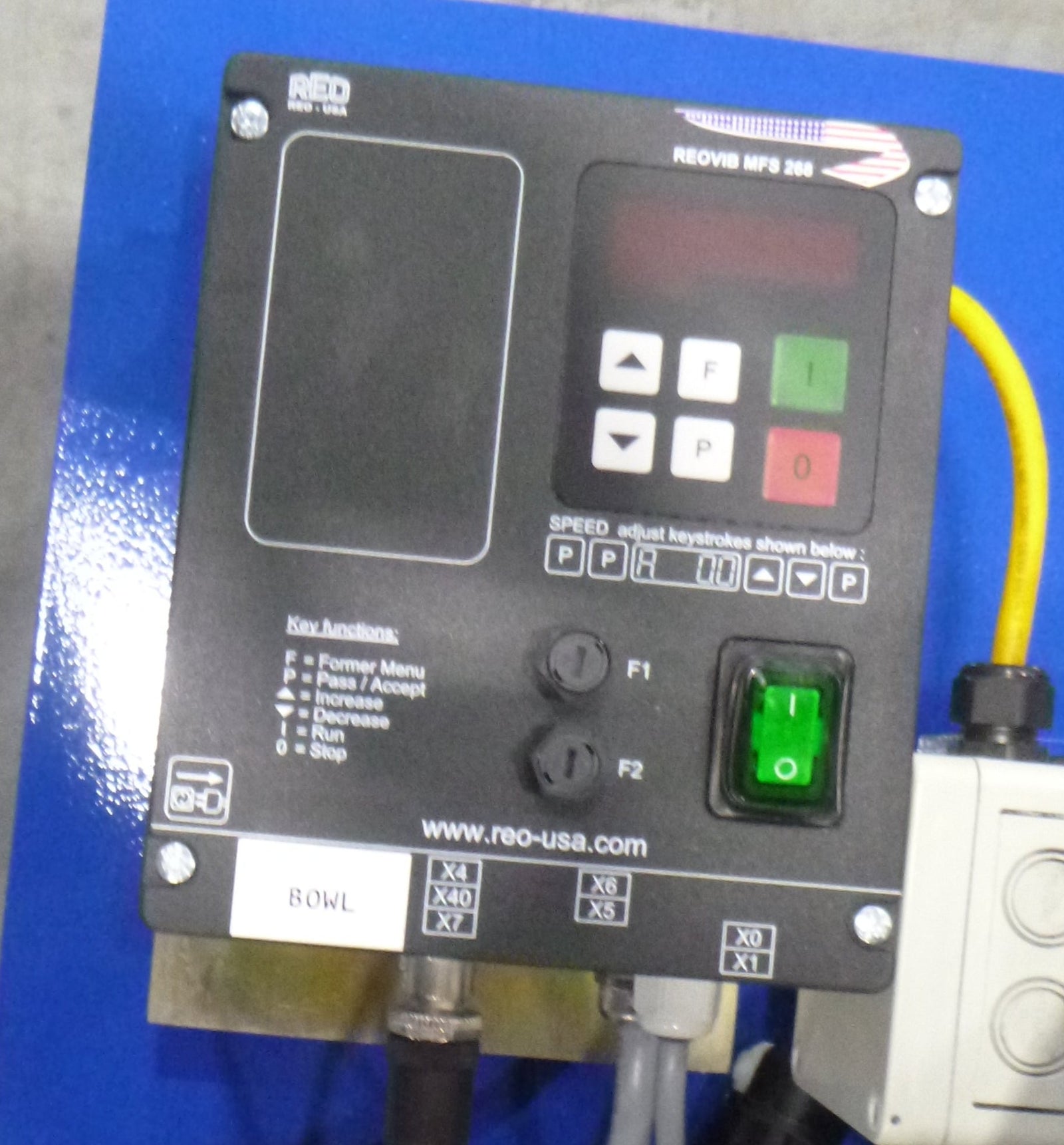

Frequency Converters: The REOVIB MFS series (e.g., MFS 168, MFS 268, MFS 368) generates variable drive frequencies and amplitudes independent of mains voltage, allowing operation at any frequency within the device’s range (e.g., 5–150 Hz). This is ideal for fine-tuning to the feeder’s resonance frequency, reducing manual tuning and improving efficiency.

-

Digital Control: MFS series controllers use digital technology with LED/LCD displays for easy parameter adjustment without opening the housing. Some models feature patented automatic resonance frequency tracking using acceleration sensors.

-

Control Inputs/Outputs: Support analog signals (0–10 VDC, 0–20 mA) and fieldbus connections (e.g., Profibus, CAN bus, EtherCAT, DeviceNet) for integration with higher-level control systems.

-

Phase-Angle Control: REOVIB SMART and MTS series use thyristors or triacs for phase-angle control, adjusting voltage to the feeder’s magnet to control vibration amplitude. This provides precise regulation of material flow.

-

Generic Solid-State Vibratory Controllers:

-

Phase-Angle Control: Like REO, most solid-state controllers use thyristors or triacs to vary voltage, controlling vibration amplitude. This is standard for bowl or linear feeders operating at mains frequency (50/60 Hz) or double (100/120 Hz).

-

Frequency Control: Some solid-state controllers offer variable frequency regulation, but not all provide the same range or precision as REO’s MFS series. Generic models may require manual tuning to match the feeder’s natural frequency, which can be less efficient.

-

Analog/Digital Operation: Many solid-state controllers support analog inputs (0–10 V, 4–20 mA) for setpoint adjustment, but digital interfaces or advanced displays may not be standard in lower-cost models. Fieldbus integration is less common in basic models.

-

Switching Capability: Some controllers, allow switching between AC "full wave" (e.g., 100/120 Hz) and DC "half wave" pulse outputs (50/60 Hz) via a toggle switch, offering flexibility for different feeder types.

-

Phase-Angle Control: Like REO, most solid-state controllers use thyristors or triacs to vary voltage, controlling vibration amplitude. This is standard for bowl or linear feeders operating at mains frequency (50/60 Hz) or double (100/120 Hz).

Comparison: REO controllers stand out for their advanced frequency converters (MFS series) with automatic resonance tracking, which is not universally available in generic solid-state controllers. While both use phase-angle control, REO’s digital interfaces and broader fieldbus compatibility provide superior integration and adjustability. Generic controllers may suffice for simpler applications but often lack the same level of precision or automation.

2. Features and Adjustability

-

REO Vibratory Controllers:

-

Series Variety: Include SMART (cost-efficient phase-angle control), MTS (single, dual, or three-channel phase-angle controllers), and MFS (frequency converters). Each series targets specific needs, from basic to advanced applications.

-

Adjustability: Offer soft-start settings, mains voltage compensation for consistent amplitude, and overflow/level control via relays. MFS series allows precise frequency adjustments in 0.1 Hz increments.

-

Protection and Mounting: Available in IP20 to IP65 housings, supporting DIN rail, back panel, or standalone installations. This flexibility suits diverse environments, from control cabinets to harsh industrial settings.

-

Certifications: Many models are UL/CSA-certified, ensuring compliance with international standards.

-

Monitoring: REOVIB includes sensors and devices for vibration amplitude, acceleration, and performance monitoring, enhancing system diagnostics.

-

Series Variety: Include SMART (cost-efficient phase-angle control), MTS (single, dual, or three-channel phase-angle controllers), and MFS (frequency converters). Each series targets specific needs, from basic to advanced applications.

-

Generic Solid-State Vibratory Controllers:

-

Adjustability: Typically include soft-start, amplitude control via potentiometers or analog signals, and sometimes track control for overflow management. However, fine frequency adjustments (e.g., 0.1 Hz) are less common unless specified.

-

Protection and Mounting: Often available in IP20 or higher enclosures, with DIN rail or panel mounting common. Sealed enclosures (e.g., aluminum) are used in some models for durability, but IP65 is not always standard.

-

Certifications: Certifications vary by manufacturer; UL/CSA compliance may not be universal in lower-cost models.

-

Monitoring: Basic models may lack advanced sensors or diagnostics, though some include track control or amplitude feedback. High-end generic controllers may offer similar features to REO but are less consistent across brands.

-

Adjustability: Typically include soft-start, amplitude control via potentiometers or analog signals, and sometimes track control for overflow management. However, fine frequency adjustments (e.g., 0.1 Hz) are less common unless specified.

Comparison: REO controllers offer more advanced features, such as precise frequency control, automatic resonance tracking, and comprehensive monitoring, making them suitable for complex applications. Generic solid-state controllers are often more basic, with fewer options for fine-tuning or integration, though high-end models may approach REO’s capabilities.

3. Applications

-

REO Vibratory Controllers:

- Designed for vibratory feeders, conveyors, and hoppers in automation, packaging, and assembly lines. The MFS series excels in applications requiring precise frequency matching (e.g., high-speed sorting).

- Multi-channel MTS controllers support systems with multiple feeders or hoppers, ideal for integrated feed stations.

- Suitable for industries needing robust, customizable solutions with fieldbus integration for PLC-controlled environments.

- Designed for vibratory feeders, conveyors, and hoppers in automation, packaging, and assembly lines. The MFS series excels in applications requiring precise frequency matching (e.g., high-speed sorting).

-

Generic Solid-State Vibratory Controllers:

- Used in similar applications (bowl feeders, linear tracks, hoppers) but may be limited to simpler setups unless specified for advanced frequency control.

- Often found in cost-sensitive applications where basic amplitude control is sufficient, such as small-scale packaging or assembly.

- Less likely to support complex multi-channel systems or fieldbus integration unless from premium manufacturers.

- Used in similar applications (bowl feeders, linear tracks, hoppers) but may be limited to simpler setups unless specified for advanced frequency control.

Comparison: REO controllers are better suited for high-precision, multi-component, or integrated systems due to their advanced control options and connectivity. Generic controllers are more versatile for general-purpose or cost-sensitive applications but may not match REO’s performance in demanding scenarios.

4. Cost and Accessibility

- REO Vibratory Controllers:

-

Generic Solid-State Vibratory Controllers:

- Cost varies widely by brand and features. Basic models are typically cheaper, suitable for small-scale operations, while advanced models with frequency control or digital interfaces may approach REO’s cost.

- Widely available from various manufacturers like Moorfeed Corporation, off-the-shelf solutions for quick deployment.

- Cost varies widely by brand and features. Basic models are typically cheaper, suitable for small-scale operations, while advanced models with frequency control or digital interfaces may approach REO’s cost.

Comparison: REO controllers are likely more expensive but offer premium features and customization. Generic controllers provide cost-effective options for simpler applications but may lack the same level of support or sophistication.

5. Advantages and Disadvantages

-

REO Vibratory Controllers:

-

Advantages:

- Advanced frequency control with automatic resonance tracking (MFS series).

- Robust integration options (fieldbus, analog signals).

- Comprehensive monitoring and diagnostics.

- Wide range of protection classes (IP20–IP65) and certifications.

-

Disadvantages:

- Potentially higher cost.

- Complexity may be overkill for simple applications.

-

Advantages:

-

Generic Solid-State Vibratory Controllers:

-

Advantages:

- Cost-effective for basic applications.

- Wide availability from multiple manufacturers.

- Sufficient for basic vibratory feeder setups.

-

Disadvantages:

- Limited frequency control and automation in basic models.

- Less consistent advanced features or certifications across brands.

- May require manual tuning or lack robust diagnostics.

-

Advantages:

Conclusion

REO vibratory controllers, particularly the REOVIB MFS and MTS series, offer advanced features like precise frequency control, automatic resonance tracking, and robust integration, making them ideal for complex, high-precision vibratory feeder systems in automated industries. Generic solid-state controllers are more cost-effective and suitable for simpler applications but often lack the same level of fine-tuning, connectivity, or diagnostic capabilities. For applications requiring basic amplitude control, a generic controller may suffice, but for demanding, integrated systems, REO’s controllers provide superior performance and flexibility. For more information on the wide variety of controllers we provide or for integration assistance contact us at support@moorfeed.com.